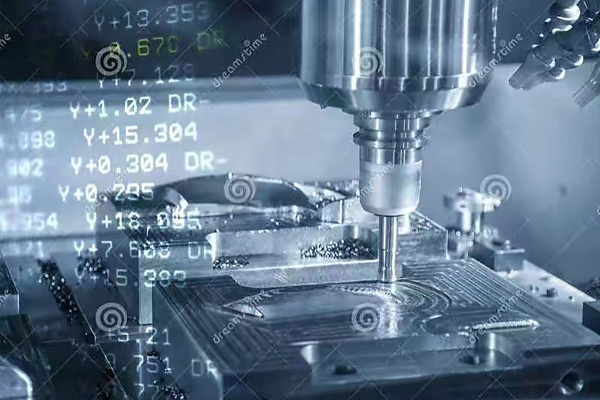

The company has accumulated rich experience in the research and development and production of precision molds and continues to innovate, and has mastered the manufacturing technology of precision molds. . In terms of precision, under normal circumstances, the company can control the precision of the mold to ±5μm, and the highest precision can reach ±2μm. For large-size molds (more than 1.5 meters long), the above precision can be obtained. According to the data published in "Mold Industry", Vol. 46, Issue 3, 2020, 5μm domestic molds can reach no more than 22%, and 2μm domestic molds can reach no more than 11%). The two bending processes are optimized into one process, and the outer R angle can reach the limit R0.9mm. Based on the precision mold processing technology, the company achieves high yield of precision structural components. For example, the precision molds produced by the company are provided with a rotating shaft and a bending wheel on the fixed block, and the roller is bent to avoid causing the surface of the structural component. damage and improve the yield of processing.

Manufacturing Process Innovation

The manufacture of precision structural components involves core processes such as extrusion molding, stamping, and CNC machining. The company's specific innovations are as follows:

At present, it is a common trend in the electrical industry to process aluminum materials into frames for the decoration of electrical frames, and then meet the needs of various types of products through anodizing, coloring and other processes. Strong, corrosion-resistant, fast heat dissipation, green and environmentally friendly and easy to recycle, it is deeply welcomed by downstream brand home appliances. With the increasingly fierce market competition, downstream deep processing has higher and higher requirements on the appearance and quality of blank materials, which puts forward higher requirements for upstream raw materials. In order to meet the requirements of the plasticity of the extruded product, the customized shape and color of the customer, it is necessary to adjust the material composition to meet the individual needs of the market.

TEL

/

/

ADD

/

Address: No. 3, Xinqing 6th Road, Xinqing Science and Technology Industrial Park, Doumen, Zhuhai